Importance of Shop Drawings in Construction

Shop drawings serve as detailed representations of construction information found in the initial documents, but with added depth and intricacy, often crafted by contractors or fabricators. These drawings delve into finer specifics, revealing the manufacturing and installation processes crucial to the project’s execution. They’re the cornerstone of fabrication industries, playing a vital role in the Construction Document Submittal Process across various construction and restoration endeavours.

At the core of the design industry lie architectural drawings, meticulously crafted technical illustrations showcasing comprehensive construction details. Utilising symbols, letters, and precise lines, these drawings portray the building components with meticulous accuracy, maintaining consistency through specific measuring scales. Their significance spans across numerous construction aspects, prominently employed in building, architecture, and design endeavours.

In today’s construction, managing costs and uncertainties is tough. AutoCAD and steel shop drawings help coordinate work between parties, boosting designer productivity. This article highlights their crucial role in streamlining construction, reducing crises in time, money, and labour.

How Are They Made?

Shop drawings typically originate from contractors, subcontractors, or fabricators. These drawings expand upon the initial design plans created by project design teams, offering a more intricate view for installation and production purposes. Before fabrication commences, these drawings are usually reviewed by the design team a couple of times to ensure alignment with the design and specifications.

During the shop drawing preparation phase, suppliers or contractors often make on-site visits to confirm project dimensions accurately. This interactive process ensures that the final drawings align perfectly with the intended design and meet the project’s specific requirements.

Key Elements in a Shop Drawing

A shop drawing is a comprehensive document encompassing essential details for streamlined project execution:

| Project Identification: | Includes project title, number, and revision dates for tracking progress and updates.

|

| On-site Verification: | Notes key dimensions at the job site that necessitate review and confirmation before fabrication and installation, ensuring precise execution in accordance with site-specific requirements. |

| Detailed CAD Illustrations: | Showcases the prefabricated component from multiple angles using intricate CAD drawings, offering a comprehensive view of the intended structure or part. |

| Fabrication Data: | Encompasses crucial information for manufacturing, such as precise physical dimensions, material specifications, manufacturing processes, and specific instructions to ensure accurate production. |

| Assembly Guidelines: | Provides step-by-step instructions, connection diagrams, and a list of necessary materials for successful component installation or assembly. |

| Compliance with Design Requirements: | References outlining how the prefabricated design aligns with the original design and construction documents, ensuring adherence to specified requirements. |

| Deviation Notations: | Notes any deviations or alterations from the original design or construction documents, highlighting changes made during the detailing process. |

These elements collectively form a comprehensive shop drawing, serving as a blueprint that guides manufacturers, fabricators, and installers toward successful project completion while adhering to specified design and construction parameters.

Shop Drawings vs. As-Built Drawings: Understanding the Contrast

In the construction and fabrication realm, shop drawings and as-built drawings stand as prevalent terms. However, distinguishing between the two is essential. In essence, shop drawings serve as a comprehensive roadmap detailing the assembly or fabrication process of a project. Conversely, as-built drawings represent a visual depiction of the project’s final, completed form.

The importance and benefits of Shop Drawings

Shop drawings are pivotal in the construction and fabrication landscape, especially for prefabricated elements like structural steel, precast concrete, and electrical layouts. They act as detailed guides for manufacturing and installation, aiding in coordinating various project components and serving as essential references for design teams.

The significance of shop drawings extends beyond mere illustrations; they play a vital role in optimising construction schedules, aiding in accurate cost estimation, and improving overall production quality. These drawings provide a comprehensive overview, fostering efficient collaboration and communication among stakeholders involved in multifaceted activities.

Facilitating engineering accuracy and analysis, shop drawings are integral in the construction document submittal process for crucial projects, ensuring clarity in design concepts and providing precise specifications for assembly and construction processes.

In the architectural, engineering, and construction sectors, shop drawings hold multifarious applications. They assist engineers, architects, and manufacturers in assessing design accuracy, ensuring structural integrity, and confirming material choices and assembly instructions.

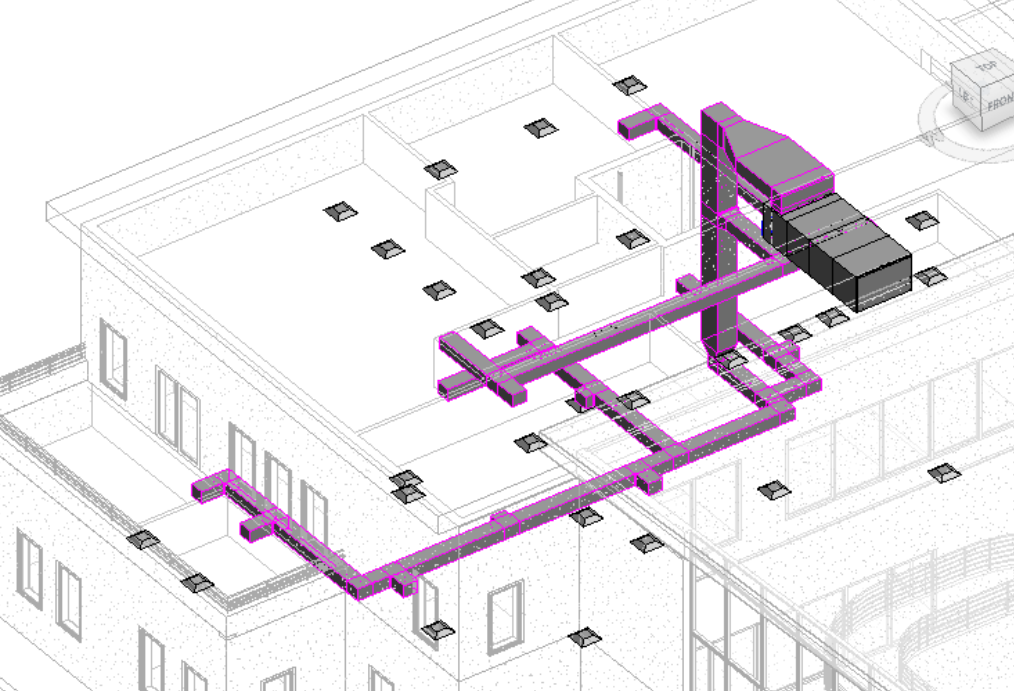

MEP professionals also rely on these drawings for clear directives on ducting, electrical components, and pipework during construction. Furthermore, in conjunction with BIM 3D modelling, shop drawings offer a precise design model, optimise timelines, and facilitate effective cooperation among cross-functional tasks.

Elevation, section, and detail view drawings within shop drawings serve distinct purposes, delineating product specifics, construction elements, and intricate production details. Utilising tools like AutoCAD streamlines their creation, enabling precision and efficient modifications.

Shop drawings act as references to design drawings and specifications, ensuring alignment with professional standards and codes, thereby minimising misunderstandings and guaranteeing accurate information for complex construction details. Their focus on product or installation particulars, omitting extraneous data, underscores their importance in achieving manufacturing clarity and meeting client demands effectively.

Point to consider

It is also important to know that Shop drawings possess inherent clarity, enabling contractors to grasp crucial details like dimensions, materials, timelines, and installation processes effortlessly. Their unique characteristics render them indispensable across all critical stages of construction, ensuring seamless comprehension for all involved parties.

Work with us!

In today’s dynamic construction industry, shop drawings are essential for timely, cost-effective, and accurate work. US bid Estimating offers a wide array of fabrication drawing services, including structural steel shop drawings, GA drawings, 3D modelling, and more. With years of experience and a skilled CAD team, we’re your one-stop solution for all fabrication drawing needs.